#Servo motor arduino pet feeder android

This causes a lot of discomfort for the pets Several pet feeders such as Arduino-based Food and Water Dispenser for Pets with GSM Technology Control3, Pet feeding Dispenser using Arduino and GSM Technology4, GSM controlled dog feeder and automatic water dispenser using RASPBERRY PI which work basically on sending SMS to the pet owners at the preset feeding time5 Design of Pet Feeder using Web Server as Internet of Things Application2, Automatic Pet Monitoring and Feeding System Using IoT6, Smart Dog Feeder Design Using Wireless Communication, MQTT and Android Client which interacts with other hardware like ultrasonic sensor, servo motor, Wifi module (ESP8266 module) and web server7. Nowadays, people are busier and because of this, they tend to forget about feeding their pets at the right time. Dogs were kennel confined mostly (207 (16.5%)) in the high income residential areas, while all dogs in transit areas were free-roaming1.

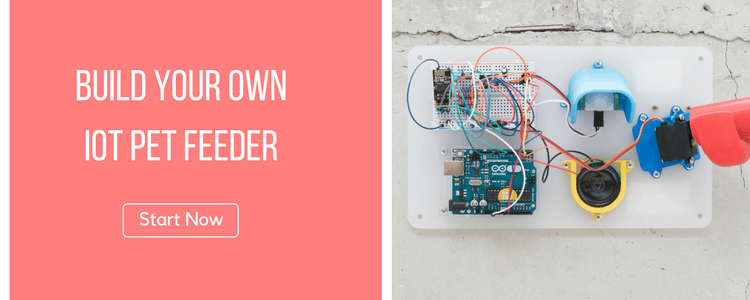

Dog management ranges from intensive (kennel confirmed) system in 331 (26.3%), to extensive (free roaming) system in 927 (73.7%) dogs. Research has shown that in about 16,348 household compounds in Ilorin, Nigeria out of 1,258 dogs, 621(49.4%) of dogs were kept primarily for security of premises, 205 (16.3%) were kept for breeding and commercial ventures, 184 (14.6%) were kept as pets, 103 (8.2%) were kept essentially for game hunting, 98 (7.8%) were used for multiple purposes and 47 (3.7%) were raised as source of meat. Popular pets are often noted for their attractive appearances, intelligence, and relatable personalities. Pet or companion animals are kept primarily for a persons company, protection, or entertainment rather than as a working animal or laboratory animal. Keywords: Microcontroller, Load cell sensor, Servo motor, LCD, Real time clock, Pet feeder. The experimental results obtained The automatic pet feeder system has highly made pet feeding easy and cost-effective. The firmware of the system was developed in C language using a MikroC ® development environment. The system also dispenses water to the pet at the specified time. At the set time, the feed is dispensed until its weight measured with a load cell reaches the preset weight value based on the consumption level of each pet. The feeder system has a battery backed-up DS 1307 real time clock that is set to the current time and the feed dispensing time.

This paper is an automatic pet feeder system which feeds pet with food and water at predetermined time interval. I'm hoping that turning force and jamming aren't an issue for me.Microcontroller-based Automatic Pet Feeder System with Load Sensorĭepartment of Electronic and Electrical Engineering Obafemi Awolowo University, Ile-Ife, NigeriaĪbstract:- Most pets owners cannot stay at home to feed their pets several times a day or impatience in feeding them due to their busy schedules.

Will post more when I finish up and test this thing out. If the speed is indeed an issue, I'm thinking that if you just set the initial delay to 8 hours and planned accordingly, it would work as it's supposed to even if it resets after one cycle. In application this would essentially just feed my food crazy cats every 3 seconds until they food coma'd next to the bowl. The servo was turning after the initial delay, then the arduino would reset and the initial delay would start over. If the slower speed isn't powerful enough to turn the crank, I may have a possible solution. So I'm hoping that when's it all assembled, it will have enough power to turn the rubber fins, which seem to be incredibly sticky. One of the potential problems, though, is that the slower the servo the less torque it has as well. I slowed the speed of the servo down and haven't had any issues with it yet (servo.write(30)). I had issues with my Arduino board resetting from the high power draw to start the servo (same board and same servo as listed). Taking a cue from the 3D printed pet feeder 'ible, you could have the servo rotate a tiny bit backwards before going forwards to dispense the food.

I had some thoughts already that could be fun to experiement with: About halfway through (bought all materials, have arduino programmed, waiting for glue to dry on crank).

0 kommentar(er)

0 kommentar(er)